|

shandong double crane machinery manufacturer Co.,ltd.

|

animal feed pellet machine for sale with 3T per hour animal feed pellet mill cattle feed machine price

| Price: | 11000.0 USD |

| Payment Terms: | T/T,T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Shandong double crane brand ring die feed pellet machine is used to make the chicken animal livestock cattle feed pellet for middle feed mill .

Brief Introduction:

SZLH 320 animal poultry feed pelletizing machine is used to press the raw material crushed and

mixed into pellet for feed mill or priviate farm. It is aiso widely applied to aquaculture,livestock and

poultry feed making. Therefore,it is a machine with multi-functions for your wide choice. The final

pellet produced is smooth and without smash for storage and sale.

Structure:

It consists of feeding device, hardening and tempering device, conditioner device, press chamber

transmission system, overload protection ...

1.Feeder:

is driven by the motor to convey the raw material into conditioner with adjustable speed.

It is consist of inlet,shaft, spiral thread and outlet.After the motor is switched on, The shaft

rotates at first, then the spiral thread push the raw materila forward to finish conveying.Because

the raw material is scattered and make a spiral motion inside the feeder, therefore to avoid the

blocking or caking. Feeder can be made in carbon steel or stainless steel according to the customer requests. Our SZLH 320 ring die poultry feed pellet mill uses 0.75 KW motor to drive the feeder running.Motor is prime quality china brand. The feeder speed ranges from 20 to 120rpm,

so the conveying is very fast .

2.Conditioner:

There is a stirring shaft installed many adjustable and repalced paddles in the cylinder body.

After conditioner runs,the raw material powder makes two motions:one is to rotate around the shaft, the other is to move forward,conbined motions is like a spiral track.The conditoner rotating speed is about

150-450r/min, if the rotation speed is certain,you can reduce the angle between the shaft and paddle to prolong the conditioning time because each paddle pushing force is lowered.

1. Steam conditioner make aging treatment on powder feed material.

2. Steam conditioner for sterilization processing powder feed material.

3. Steam conditioning equipment can significantly improve the pellet

feed water resistance.

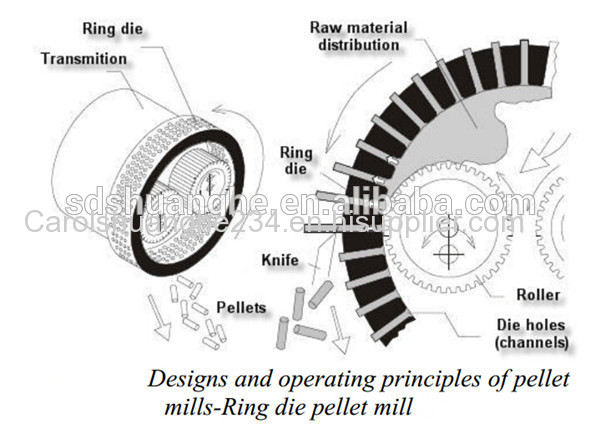

3.Pressing chamber:

How a pellet is formed ? there are three forces in the pressing chamber to form the final pellet:

1. Roll force: the force from the roll is acting on the material.This is the force that compresses material or extrudes it through the die holes.

2.Die force:This is the force from the die that resists the flow of material though the holes.This force is designed into the system to produce the flow resistance or back pressure that forces individual feed particles together,where they bond and form pellet.

3.Slip resisting force: finally, there is a frictional force derived from material contact with the die.This particalforce keeps the material from squirting along the face of the die in front of the roll.This force is related to the pressure exerted by the roll and the frictional characteristics of the feed itself.This force is simillar to that which brings a car to a stop when the brakes are applied.

Technical data:

Item NO. | SH-200 | SH- 250 | SH-300 | SZLH-320 | SZLH-350 | SZLH-420 | SZLH-508 |

Output (t/h) | 0.4-0.6 | 1-1.5 | 1.5-2.5 | 2-4 | 3-6 | 8-10 | 10-20 |

Main Power(kw) | 15 | 22 | 30 | 37 | 55 | 110 | 132 |

Feeder Power(kw) | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 |

Conditioner(kw) | 0 | 2.2 | 2.2 | 2.2 | 2.2 | 5.5 | 7.5 |

Inside Dia (mm) | 200 | 250 | 300 | 320 | 350 | 420 | 508 |

Roller Qty (pc) | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

Feeder Speed (rpm) | 20-120rpm | ||||||

Conditioner Speed | 360 rpm | ||||||

Feed Pellet Diameter | Φ1.5,Φ2,Φ2.5,Φ3,Φ3.5,Φ4,Φ4.5,Φ5,Φ6,Φ8,Φ10,Φ12mm | ||||||

Pellets shaping rate | ≥ 95% | ||||||

Steam Pressure | 0.1-0.4Mpa | ||||||

Steam Consumption | ≥0.1-0.3T/H | ||||||

Pelleting Moisture | About 15.5% | ||||||

Pelleting Temperature | 70-90°C | ||||||

Pellet mill noise | ≤85dB(A) | ||||||

Application | Use to produce feed pellet for fish/poultry/chicken/rabbit/sheep/cattle/cow farm. | ||||||

Raw materials:

1. Cereals:soybean, maize,corn, grain,sorghum,corn flour , wheat flour ,crop stalks (corn stalk,sorghum stalk, cotton, rape stalk, peanut seedling, sunflower stalk), chaff, grasses, shrubs

2. Coarse fiber: wheat bran, corn stalk, soybean meal,grass meal,rice husk, grass, groundnut shell,cottonseed hull

3. Additives: molasses, vegetable oil, bone meal, vitamin

Application:

it can be widely used in large, medium and small feed mill, livestock poultry farm, individual farmers, small and medium sized farms, as well as feed manufacturer plant.

Feed Hammer Mill → Feed Mixer → Ring Die Feed Pellet Mill → Pellet Cooler → Vibrating Screener→bagging

About Professional Service:

1.We devote to all-round service of all the products from shipment

to maintenance.

2.Our professional service include:free training,guidance,onsite installation,and debugging.

3.After selling, we provide the warranty of one year and free technical guidance and spares parts supply.

4.If your equipments have any problems, we will help you to solve

online or onsite in time.

5.Welcome oversea agents to join us expand internation market.

6.Welcome to contact us for further information!

RFQ:

1.Are you manufacturer or trading company?

R:Our company is manufacturer and public company,we have been specialized in this field more than ten years.our company's factory covers an area of 67000 square meters,registered capita60 Million RMB.

Located in Dezhou city,Shandong Province.

2.How can we promise the equipment quality?

R:Our company pass European Union GS Safety Certification,ISO9001 Quality Management System Certification,Chinese Credit Enterprise Association, AAA Quality Credit Enterprise Member, Well-known Trademarks In China.

We have professional R&D and production team can promise all equipment is qualifyed befor deliver to customer.

3.If we want to establish a feed production line,can you help us?

R:Yes,our company can provide service of free design,training,guidance,onsite installation,and debugging.

Only need customer tell us which type animal feed do you want to produce,production capacity demand,we will recommend you the best design and offer.