|

shandong double crane machinery manufacturer Co.,ltd.

|

Feed hammer mill maize grinding mill machine corn grinder for chicken feed poultry feed milling machine

| Price: | 4000.0 USD |

| Payment Terms: | T/T |

| Place of Origin: | Shandong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Feed hammer mill is used to crush the raw material such as corn,maize,soybean into particle or powder for pelleting with high efficency and low noise.

Feed hammer mill maize grinding machine corn grinder for chicken feed poultry feed milling machine

Description

Grinding or particle-size reduction is a major function of feed manufacturing. Many feed mills pass all

incoming ingredients through a feed hammermill, feed grinder,feed grinding machine,feed crusher for

several reasons: (a) clumps and large fragments are reduced in size,(b) some moisture is removed due to

aeration, and(c) additives such as antioxidants may be blended. The grinding of ingredients generally

improves feed digestibility, acceptability, mixing properties, pelletability, and increases the bulk density

of some ingredients.

It is accomplished by mechanical operations involving impact, attrition. Therefore,hammer mill is the

best choice for the feed manufacturing.

Features

1. Universal type product, stable performance, easy for installation, operation and maintenance.

2. Coupling direct drive is adopted, generating high transmission efficiency and accurate drive ratio.

3. Built-in grinding rotors and efficient grinding without dead corner.

4. Portable operation door with convenience, strength-saving and high security.

5. A variety of sieve sizes are available to choose and the wrap angle of the sieve is large up to 300°

6. Scientific and reasonable hammer arrangement and reasonable gap between hammer and the screen, ensure uniform fineness of finished products, little vibration and high productivity.

7. There are two groups of pin holes on the rotor disc, uniformly distributed on two concentric circles of

different diameters, by which coarse and fine grinding can be achieved.

Techinal Data

Item Name | SFSP56*32 | SFSP56*40 | SFSP60*60 | SFSP66*80 | |

Motor Power(KW) | 22/30 | 30/37 | 55/75 | 90/110 | |

Production Capacity | 1-2t/h | 3-5t/h | 4-10t/h | 5-15t/h | |

Hammer Quantity | 30pcs | 48pcs | 70pcs | 90pcs | |

Screen Quantity | Screen 2pcs,high output,good crush effect | ||||

Screen Hole Diameter | 1.5,2,4,6,8,10,12mm | ||||

Rotor Diameter (mm) | 560 | 560 | 600 | 660 | |

Crushing Chamber Width (mm) | 320 | 400 | 600 | 800 | |

Mainshaft Speed ( rpm ) | 2970 | 2970 | 2970 | 2970 | |

Hammer of Line Speed(m/s ) | 103.8 | 98 | 100 | 105.8 | |

Bearing Number. | 2312 | 2314 | 2214 | 2218 | |

Screen Size(mm) | 840*270*2 | 712*395*2 | 850*618*2 | 850*795*2 | |

Anti-vibration Pad | 4 | 4 | 4 | 6 | |

Carbon Steel Shell Thinkness | 6mm | 6mm | 10mm |

10mm | |

Dimension and Weight | Length(mm) | 1410 | 1550 | 1900 | 2500 |

Width(mm) | 720 | 860 | 900 | 1100 | |

Height(mm) | 970 | 1130 | 1250 | 1350 | |

Weight | 0.8Ton | 1Ton | 1.5Ton | 2Ton | |

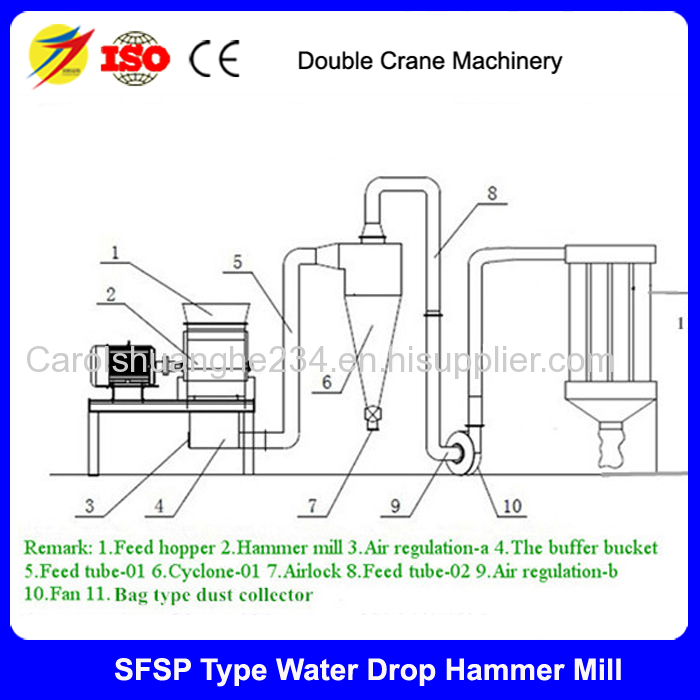

Working principle

Hammer mills are mostly impact grinders with swinging or stationary steel bars forcing ingredients against

a circular screen or solid serrated section designated as a striking plate.

Material is held in the grinding chamber until it is reduced to the size of the openings in the screen. The number

of hammers on a rotating shaft, their size,arrangement, sharpness, the speed of rotation, wear patterns, and clearance at the tip relative to the screen or striking plate are important variables in grinding capacity and the appearance of the product.

Heat imparted to the material, due to the work of grinding, is related to the time it is held within the chamber

and the air flow characteristics. Impact grinding is most efficient with dry, low-fat ingredients, although many

other materials may be reduced in size by proper screen selection and regulated intake.

Associated with grinding feeds, a sieving system is required which classifies materials to any desired particle

size. The "overs" in this system may be re-ground or rejected. The "throughs" may be selected to comply with livestock and poultry requests for size and mixed according to formula specifications. Feeds sifted through

3-8mm opening have been successfully used for increasing survival and growth of livestock and poultry.

Hammermill or impact grinding of dry feeds, especially cereal grains, creates particles within the range

called "dust", and a dust-collecting system may be necessary to remove this. An excess of dust in the feed

may lead to gill disease, a situation where organic matter adhering to gills becomes a nutrient for bacteria or parasites.

Usage

it can be widely used in large, medium and small animal feed factory, livestock farm,poultry farm,individual farmers, small and medium sized farms, as well as feed manufacturer plant.

Cetifcate

About Professional Service:

1.We devote to all-round service of all the products from shipment to maintenance.

2.Our professional service include:free training,guidance,onsite installation,and debugging.

3.After selling, we provide the warranty of one year and free technical guidance and spares parts supply.

4.If your equipments have any problems, we will help you to solve online or onsite in time.

5.Welcome oversea agents to join us expand internation market.

6.Welcome to contact us for further information!